Q1 What types and tonnage ranges does MINGXU press cover?

Our presses cover multiple structural types, including C frame, gantry type with single plungers, gantry type with double plungers, toggle type, underdrive, etc. Tonnage ranges from 1 to 400 tons, including the world's smallest press THS-1 (1 ton) and heavy-duty press like CHD-400 (400 tons).

Q2 What is the average lead time?

For 80 ton and below, the lead time is around 1-2 months. For knuckle-joint and heavy-duty model (above 80 ton), the lead time starts from 2 months.

Q3 Which certifications have MINGXU obtained?

ISO 9001:2015 (Quality Management system), CE (EU Compliance)

Q4 What precision standard do MINGXU presses meet?

Japan JIS B 6402:2020 Super Grade Accuracy

Q5 What field are MINGXU presses applied in?

Our presses are widely used in metal forming, including stator rotor, lead frame, connector, chain, heatsink, terminal, canning, etc.

Q6 How to select the appropriate press model and tonnage?

The appropriate press model and tonnage should be determined by material type and thickness, die specifications, etc. For detailed consultation, please contact our technical sales: Nick Wu (nickwu@mx-press.com).

Q7 How to obtain product specifications?

1. You can find technical parameters of each press on the website’s Product Page and download SPEC in the attachment.

2. Contact Technical Sales: Nick Wu (nickwu@mx-press.com)

Q8 What’s the characteristics of frame material?

We use ductile iron FCD500 in press main structure. FCD500 has steel-competitive properties, distinctly stronger than gray cast iron. With high toughness, superior impact resistance and fatigue durability, FCD500 is ideal for high speed operation. Meanwhile, with excellent castability and machinability, complex shapes are achievable and easier to machine.

Q9 What are the sources of core components (crankshafts/bearings)?

Crankshafts: Sourced from GIIHG, a Fortune Global 500 company.

Bearings: Sourced from Japanese NSK, Japanese KOYO, Deutsch FAG, etc.

Q10 What’s the value of Finite Element Analysis (FEA)?

FEA simulates physical systems through mathematical modeling. Optimized structure with minimal slide deformation and enhanced rigidity is achieved through FEA.

Q11 Why frames undergo annealing?

Main structures of our press go through annealing before rough machining to relieve internal stresses, enhance ductility, and develop microstructures.

Q12 Why Vibratory Stress Relief (VSR) is essential?

VSR applies sub-harmonic vibrations to relieve internal stress, stabilize metal, and ensure long-term precision.

Q13 How does the Dynamic Balancer work?

Dynamic balancer adjusts the press’s motion during operation to reduce vibration and ensure stable high-speed performance.

Q14 Where are the manufacturing centers?

2 plants in Dongguan, Guangdong:Plant I:

R&D + Machining + QA lab

Plant II: Assembly + Warehouse

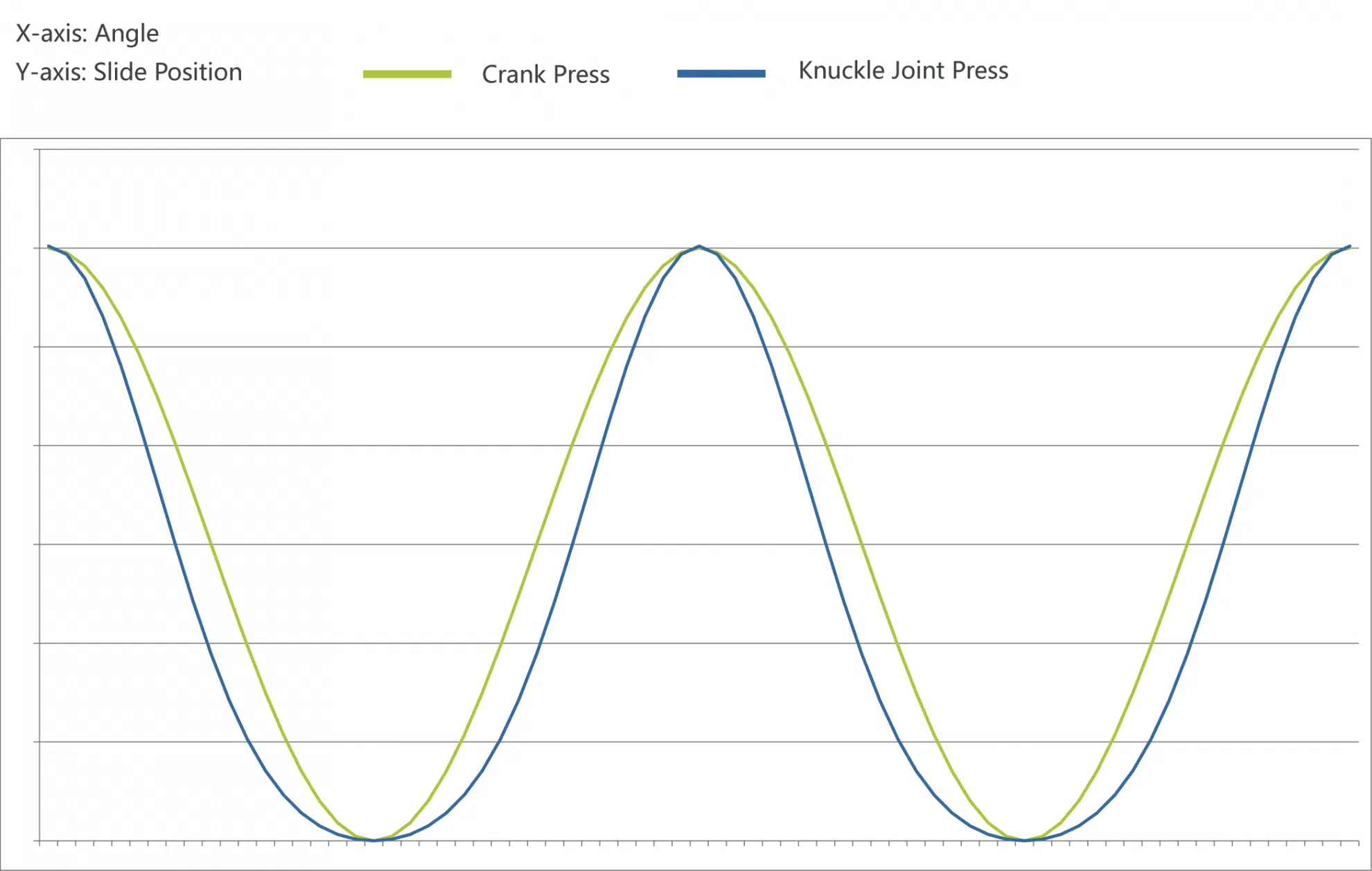

Q15 What are the differences between Crank Press and Toggle Press?

| Crank Press | Item | Toggle Press |

|---|---|---|

| Crank Connecting Rod Mechanism | Drive Mechanism | Toggle Linkage Mechanism |

| Standard sine wave Short dwell at BDC | Slide Motion Curve | Slower motion near BDC Prolonged pressure holding at BDC |

| Higher speed Simpler structure, easy to maintain Wide applicability Lower cost | Advantages | High BDC accuracy Extended die life Lower noise and vibration |

| Lower BDC pressure Limited accuracy | Limitations | Complex structure, higher cost Low mold compatibility Low SPM |

| General metal stamping Flexible production | Applications | Precision forming Deep drawing Small metal parts |

| ||