*Brochure available for download at the bottom

Function Features

- The oil cooler regulates oil temperature and maintains internal thermal balance, preventing unstable expansion caused by temperature fluctuations. This minimizes frame deformation and enhances BDC stability.

- The frame structure is optimized through finite element analysis (FEA) for rationalized design.

- High-strength cast iron frame undergoes annealing, rough machining and vibratory stress relief (VSR), thoroughly eliminating thermal stresses to ensure long-term precision.

- Centralized crank center lubrication eliminates swinging oil pipes, reducing breakage risks.

- Temperature-controlled oil cooling minimizes press thermal deformation.

- Tailored counter dynamic balancing system ensures stability during high-speed operation by compensating for upper die rebound.

- Gantry-type frame structure minimizes deflection during stamping compared to C-frame presses.

- Hydraulic slide locking/releasing device ensures press operation safety and enables easy die adjustment.

- Electric die height adjustment with position indicator enables easier operation.

- The PLC interface microcomputer control system or mobile console displays press angle, speed, and error message.

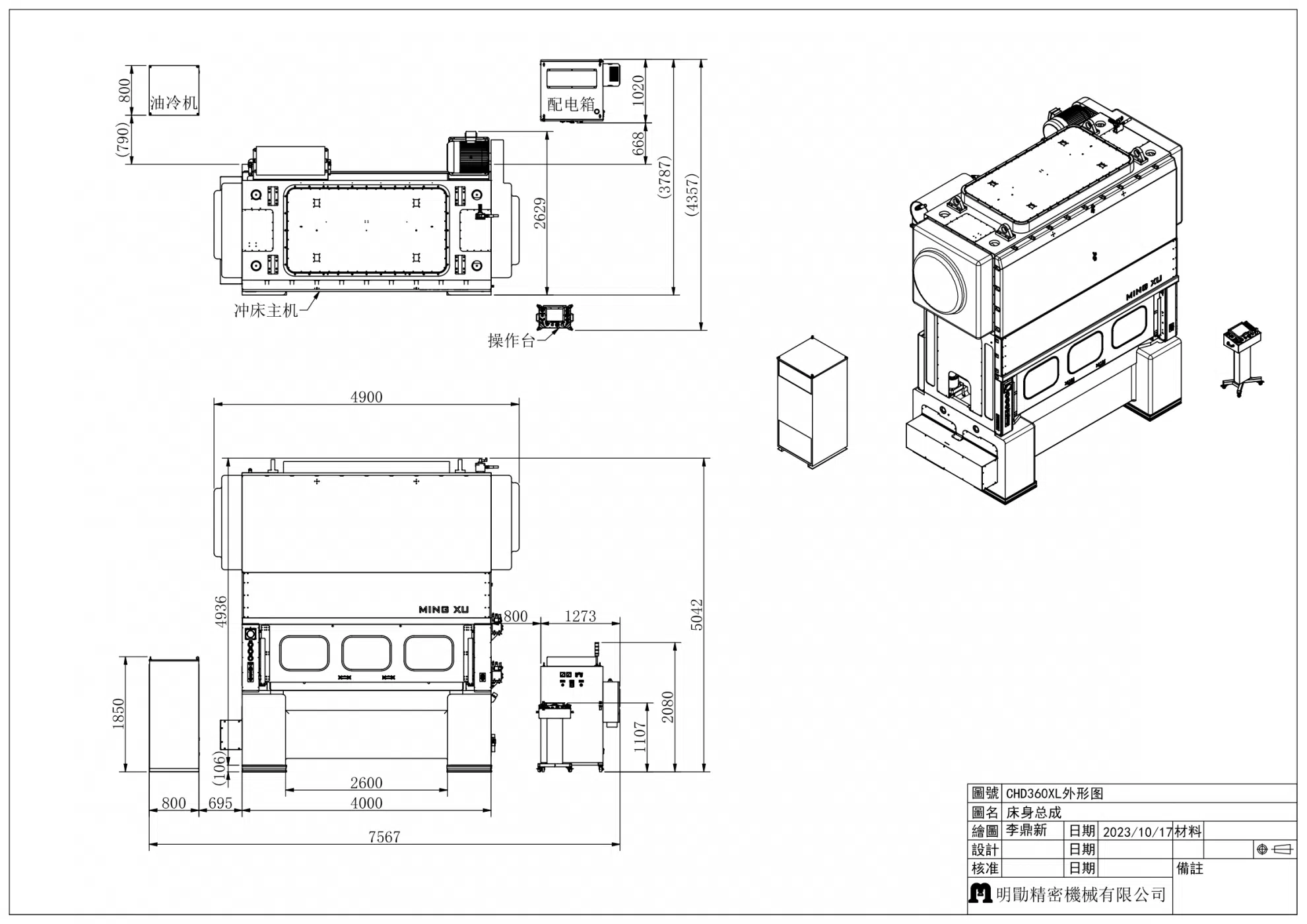

Press Dimension Drawing

Technical Parameters

| Product | CHD Gantry Four Crank Precision High-speed Press | ||||

|---|---|---|---|---|---|

| Model | CHD-400 | ||||

| Capacity | Ton | 400 | |||

| Stroke | mm | 30 | 35 | 40 | 50 |

| Speed | S.P.M | 100-260 | 100-260 | 100-260 | 100-200 |

| Die-Height | mm | 520-620 | 518-618 | 515-615 | 510-610 |

| Bolster Area | mm | 3700*1200 | |||

| Slide Area | mm | 3700*1100 | |||

| Slide Adjustment | mm | 100 | |||

| Bed Opening | mm | 3400*450 | |||

| Main Motor | HP/kW | 75 | |||

| Gross Weight (approx.) | kg | 130000 | |||

| Lubrication | Automatic Lubrication | ||||

| Speed Control | Inverter | ||||

| Clutch & Brake | Air & Friction | ||||

| Auto Top Stop | T.D.C | ||||

| Shock Absorber | Damper / Spring Damper | ||||

| # | Name | Upload Date | Download |

|---|---|---|---|

1 | CHD400-Parameter | 2025-08-07 |